Introduction

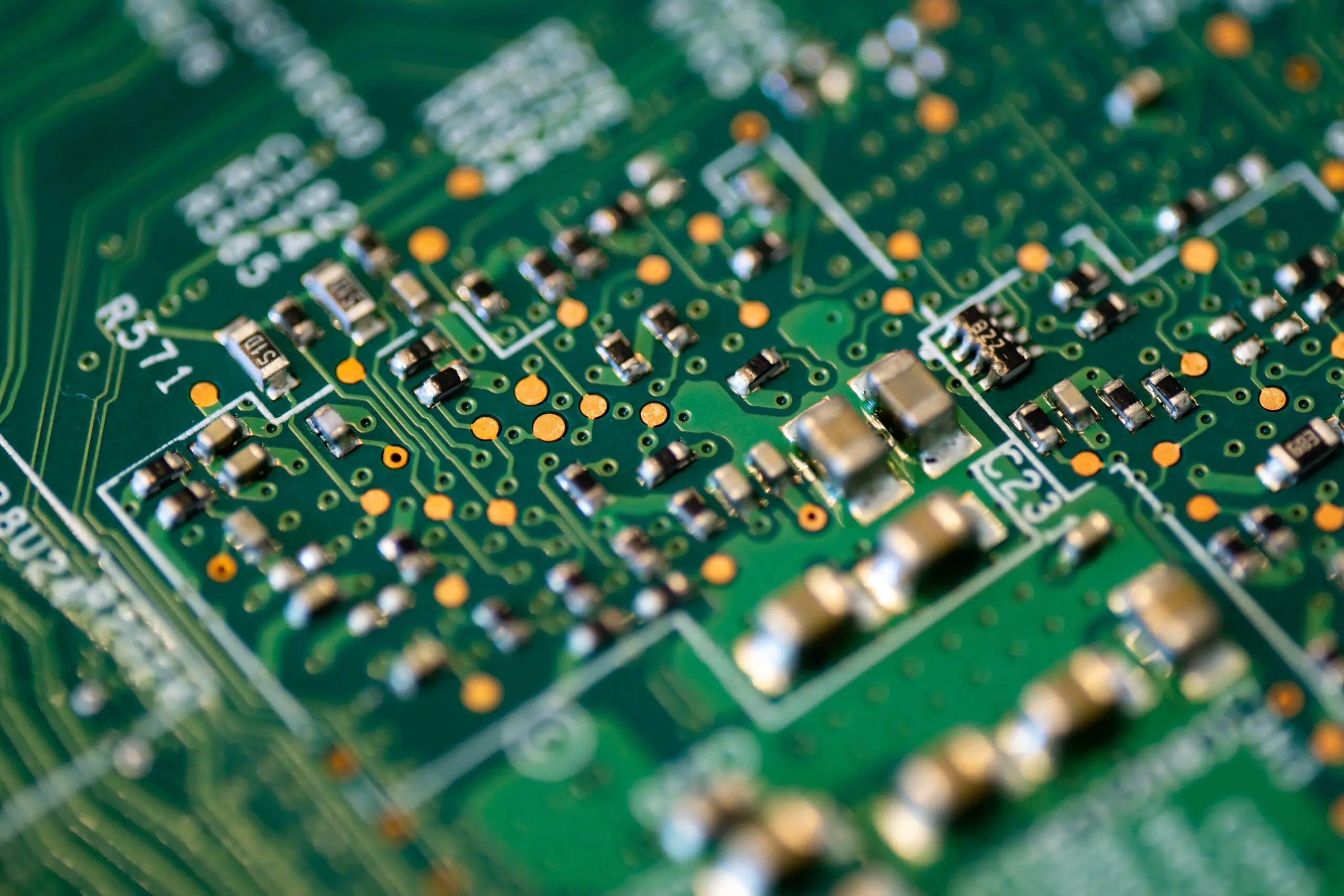

The main printed circuit board of a computer is known as the motherboard. The primary central communication authority and a connecting point with which all the external peripherals and components connect is the motherboard of a computer. The top of the base material is layered with a solder mask, due to which the color of the motherboard background is green. Let us know why are motherboards green, composition of motherboards and also the importance of motherboard’s color in this article.

Electronic circuits like motherboards are primarily green in color because they are coated with a solder mask, which is a polymer. It protects and insulates the copper traces printed on the motherboard in between the process of soldering. Solder masks of green color have been a standard for centuries in the industry. Silkscreen print is easily readable on a green background, which is why the motherboards are green in color. The green color is widely accepted as a standard color, so the manufacturers only use other colors in trial products.

History of Green Motherboard

Circuit boards were coated on surface-mounted components with hardened resin during the 1960s. The resin was dingy brown in color. A dye was added to the resin by the developers, which created a greenish color existing in circuit boards till now.

Later this color was adopted by the giant company Intel as the primary color of their motherboards, giving it priority over the rest of the lesser quality colors such as brown and black.

Why Are Motherboards Green?

Solder Mask Coating

Motherboards are primarily green in color because they are coated with a solder mask, which is a polymer. Silkscreen print is easily readable on a green background, which is why the motherboards are green in color.

Help for technicians

Another reason for the green motherboard was to reduce the eye strain of the technicians. The motherboards were created manually by the technicians. Looking at the tiny spaces and spots on the motherboard used to put stress on the eyes of the technicians.

Reduce eye strain

It was discovered by the opticians that the green light’s frequency is used to put lesser strain and pressure on the eyes. So, the green color was preferred, and it was easy to differentiate other parts on the board due to the presence of green.

Cost-Effective

Green was the random choice of the early developers, and it continued as a permanent choice because of its reasonable low-price production. Colors used to have varied prices, and the brands like IBM tried to save cash by utilization of big-scale output. They did not choose a color based on aesthetics. They preferred protective coating, which was low-priced, and the first choice was green in this regard.

Green is considered a contenting color

The color green was primarily known as an industry’s solder mask, and it was preferred on printed circuit boards during the 1960s when surface mount parts began dominating. Such parts were actually connected to the motherboard. It was considered a content color by the industry.

Non-spreading of color

The parts were denser and more petite, requiring some resin to keep the color from spreading. However, the use of resin started and it resulted in a brown color that was very unsightly. As a solution, they chose to append some other color pigments and, from there, were capable of producing a solder mask that resembled the lovely green color.

Environment friendly

A green motherboard is environmentally friendly because it is built with recycled material and less plastic. Since green motherboards are ecologically friendly, most companies prefer them. Nowadays, more colors are also included in the motherboards.

Other Colors on Motherboards

While the primary standard is still green, different colors have started forming their approach to the market. Some makers have decided to select and use different colors to differentiate premium motherboards from standard ones. Color options are discussed below:

1.Red

Red is used because it is a highly contrasting color, so the motherboard and its components can be differentiated. Screen-printed red labels are visible. Red motherboards were utilized earlier by the developers to show a test motherboard that was not accessible for retail sale. Nowadays, manufacturers have started making motherboards purposely in red to sell them to consumers.

Although the red color is helpful in motherboard inspection, it still does not bypass the standard green color visibility.

2.Blue

The contrast abilities of the blue color solder mask are not as good in visibility as red and green, so it is a must to use a magnifier while inspecting motherboard traces. The screen-printed labels and the blue solder mask can have a good visibility contrast in blue motherboards.

This color is chosen by manufacturers only to distinguish their product and because it is an eye-catching color.

3.White

This is the least acceptable practical color for the motherboard. Very little contrast is offered in this color and hence making it challenging to do an inspection and to ensure cleanliness as well. The white background, however, gives support to the silkscreen labels. They are costly as well because their production is significantly less in number.

4.Black

One of the problematic colors working within the motherboard is black color. The traces are difficult to identify on black background, and proper viewing from some angles is possible only with a magnifier. Heat absorption and difficulty in cleaning are other problems associated with these color motherboards. Clarity is there between the silkscreening labels and the background because of the contrast.

5.More Colors

Other colors, like yellow, orange, purple, etc., have also been utilized by the manufacturers for fulfilling the aesthetic reasons of the consumers. They are limited in number.

Importance of motherboard’s color

The color of the motherboard does not make it perform better or faster in any way. It is nowadays purely an aesthetic-based act. Color is important only as far as flashy motherboards are concerned because it creates more attraction in the see-through towers when compared with others.

Nowadays, motherboards can be customized as well. This requirement can be fulfilled by printed circuit board companies, but it can be costly. Suppose you want an aesthetically pretty color for the color scheme of a particular device. In that case, a better choice is to search for the motherboards that already have prints of that specific color you desire. It would help if you made sure that the specifications given on those motherboards match your requirements.

Difference between Motherboard and Circuit Board

All circuit boards cannot be motherboards, but all motherboards can be called circuit boards. A motherboard is a circuit board that is the main component of the computing device. It has the power to add more circuit boards through connection points. Circuit boards are specialized in doing only one task and are smaller in size.

The motherboard and the circuit board have the same production process; both insulate the boards providing electrical sourcing to their parts to their basic level.

Composition of Motherboards

Fiberglass and copper are the two primary materials of a motherboard. For the proper functioning of the motherboard, the copper gives pathways for conduction, and the fiberglass serves as an insulator. The rest of the material includes a solder mask, epoxy, and tin.

Surface-mounted components become part of the motherboard through the process of soldering. They are joined to metal paste and then reflux soldered to create its connection with the motherboard.

Motherboard Creation Process

A sheet of fiberglass fibers is formed first to fabricate the motherboard. The prepreg sheet is included with a combination of heated fiberglass sheet and epoxy resin. It is now placed in between two copper field sheets. Later, copper, which is not required, is dissolved. Ultimately, six layers are created with the needed materials. Subsequently, holes are drilled. Then tin electroplating is done.

The next step is to make the motherboard conductive. Then a photo-resistant material is placed over the board. After electroplating, the solder mask is joined. Then the color of the motherboard is applied. Green is the most commonly used color for motherboards. The final step is the placement of labels indicating the components installed in the motherboard.

Finishing process

Soldering and component installation can start after the motherboard has been tested with a pin tester to check the successful conductivity of the components. Later surface mounted components’ installation takes place. Once the surface-mounted components get placed correctly, they are then reflux soldered, which means an electrical connection is created. Then card slots, sockets, etc., are installed.

Lastly, an electrical connection is generated through the motherboard and the components. This is a position where the motherboard has gone through its finishing process and is ready for final testing.

Cleaning a Green Motherboard

It depends on the board and how you can clean it. If it is an old motherboard, you first must take out each part from it so that each component can be adequately checked. This is required because if they are not checked, then cleaning the surface can also trigger the crashing of other parts.

If the motherboard is new but does not seem clean, then take a cotton cloth and dip it into neutral cleaner or rubbing alcohol. Then clean from top to bottom with dry cotton. Be gentle while cleaning because a little harsh stroke can damage the sensitive parts and become the cause of motherboard damage.

Conclusion

The main reason motherboards were created in the beginning with the green color was because of these colors’ cost-effectiveness. Other reasons for green motherboards include solder mask coating, helping technicians in their manual work, reducing eye strain, contenting view as a color and its non-spreading color quality, and being environmentally friendly. Colors other than green are now also used by manufacturers but mostly on trial products or gaming-related circuit boards. These additional colors include red, blue, black, white, yellow, etc.

FAQ’s

1.What is a motherboard, and which material is used to make it by the manufacturers?

The main circuit board where all components of a computer are connected is known as the motherboard, and it is commonly made with material such as metal or plastic.

2.Is it a matter of concern if the motherboard’s color is not green?

No, it does not matter if the color of the motherboard is not green, but the color green is always preferred because of being environmentally friendly and cost-friendly.

3.Can users select the color of the motherboard?

Yes, nowadays, companies also allow their users to choose the motherboard’s color of their own choice as well.